|

|

- Grade Introduction

- Turning

- Turning Inserts

- Micro-Grain Cemented Carbide (Solid tools)

MICRO-GRAIN CEMENTED CARBIDE (SOLID TOOLS)

- Compared to general cemented carbide, micro-grain alloy has higher wear resistance and higher toughness.

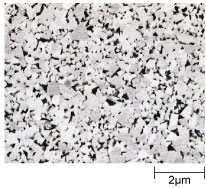

Micro-Structure of MF10

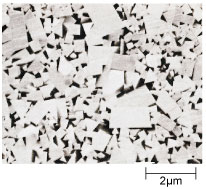

Micro-Structure of TF15

SELECTION STANDARD

| Cutting Tool | Recommended Grade | Workpiece |

|---|---|---|

| PCB Drill | SF10 MF07 MF10 MF20 |

Non-Metal |

| Solid Carbide Drill Turning Inserts Milling Inserts |

TF15 | Steel, Cast Iron |

| Solid End mill | HTi10 TF15 MF10 |

Steel, Cast Iron |

| Gear Hob Reamer Tap etc. |

TF15 MF20 MF30 |

Steel, Cast Iron, etc. |

CUTTING PERFORMANCE

<Cutting condition>

- Workpiece:

- Die steel (40HRC)

- Tool:

- ø6mm,4 flutes

- Helical Angle:

- 30°

- vc=30m/min

n=1,600min-1

fz=0.02mm/tooth

vf=128mm/min

Depth of Cut in the Axial Direction=9.0mm

Depth of Cut in the Radial Direction=0.6mm

Down Cut, Dry

GRADE CHARACTERISTICS

| Grade | Grade Characteristics | ISO | Wear Resistance | Fracture Resistance | Corrosion Resistance | ||

|---|---|---|---|---|---|---|---|

| Specific Gravity | Hardness(HRA) | T.R.S(GPa)* | |||||

| HTi10 | 14.9 | 92.0 | 3.2 | K10 | |||

| TF15 | 14.5 | 91.0 | 4.0 | K20 | |||

| SF10 | 14.9 | 92.7 | 3.8 | K01 | |||

| MF07 | 14.7 | 93.2 | 3.9 | K01 | |||

| MF10 | 14.6 | 93.0 | 4.0 | K01 | |||

| MF20 | 14.2 | 92.0 | 4.4 | K10 | |||

| MF30 | 13.7 | 90.7 | 4.3 | K20 | |||

*1GPa=102kg/mm2

**After HIP

**After HIP