|

|

- Grade Introduction

- Turning

- Turning Inserts

- Coated Carbide(PVD)

COATED CARBIDE (PVD)

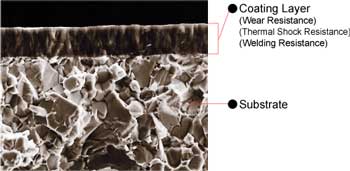

- PVD coating prolongs tool life.

- Coating of tools with sharp edges is possible without softening or changing the quality of the substrate.

SELECTION STANDARD

TURNING

FEATURES OF VP (MIRACLE)COATING

Compared to conventional coating technology, VP (MIRACLE) coating features (Al, Ti) N coating with highly increased heat resistance and adhesion strength.

APPLICATION EXAMPLES

| Insert (Grade) | CNMG120416-MA(UE6110) | WNMG080408-MV(UE6020) | |

|---|---|---|---|

| Workpiece | Alloy steel |

Stainless Steel (Fan parts) |

|

| Cutting Conditions | Cutting Speed (m/min) |

170 | 200 |

| Feed (mm/rev) | 0.14 | 0.25 | |

| Depth of Cut (mm) |

0.25 | 0.5 | |

| Coolant | Wet cutting | Wet cutting | |

| Result |  VP15TF does not experience chipping. This enables stable machining and much longer tool life. |

MJ breaker achieved 1.5 times longer tool life. |

|

| Insert (Grade) | CNMG120416-MA(UE6110) | WNMG080408-MV(UE6020) | |

|---|---|---|---|

| Workpiece | Inconel 718 (Pin) |

Sintered iron parts (FH655) |

|

| Cutting Conditions | Cutting Speed (m/min) |

31 | 120 |

| Feed (mm/rev) | 0.2 | 0.05 | |

| Depth of Cut (mm) |

2.3 | 0.5 | |

| Coolant | Wet cutting | Wet cutting | |

| Result |  VP10RT achieved 4 times longer tool life. MJ breaker for excellent chip disposal and vastly increased tool life. |

MJ breaker achieved 5 times longer tool life. |

|