|

|

- Grade Introduction

- Turning

- CBN&PCD Turning Inserts

- Sintered Diamond PCD Grade MD220

SINTERED DIAMOND PCD GRADE MD220

- Suitable for materials such as aluminium alloy, non-ferrous metals, and fibre strengthened plastic.

- Suitable for extremely high speed finishing.

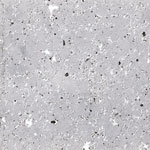

Micro-Structure of MD220

RECOMMENDED CUTTING CONDITIONS

TURNING

| Work Material | Recommended Cutting Condition | ||

|---|---|---|---|

| Recommended Cutting Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) | |

| Aluminium | 1000 (200─1500) | ─0.2 | ─3.0 |

| Aluminium Alloy (Si ≤ 16%) | 800 (200─1200) | ─0.2 | ─3.0 |

| Aluminium Alloy (Si ≥ 16%) | 600 (200─1000) | ─0.2 | ─3.0 |

| Copper Alloy | 700 (200─1200) | ─0.2 | ─3.0 |

| Strengthened Plastic | 600 (100─1000) | ─0.4 | ─2.0 |

| Glass Fiber Reinforced Plastic | 500 (100─800) | ─0.25 |

─2.0 |

| Carbon | 400 (100─600) | ─0.3 |

─2.0 |

| Ceramics | 50 (30─80) | ─0.1 | ─2.0 |

| Hard Rubber | 600 (300─800) | ─0.15 | ─1.0 |

| Wood Inorganic Board | 1300 (300─4000) | ─0.4 | ─ |

| Cemented Carbide | 15 (5─20) | ─0.2 | ─0.5 |

- (Note.1)

:1st recommendation.

:1st recommendation.

:2nd recommendation.

:2nd recommendation.- (Note.2)

- Not suitable for steel.

CUTTING PERFORMANCE

<Cutting Conditions>

- Workpiece:

- High Si Aluminium Alloy

- Tool:

- P11R,SPGN120308

- vc=200m/min

ap=1.5mm

f=0.15mm/rev

Coolant:W.S.O

NEW PETIT CUT INSERT SERIES

FEATURES

- Economical The small PCD tip delivers long tool life. Eliminates the need for regrinding, making tool management easier and economical.

- With Breaker Chip breaker formed directly on the PCD portion delivers superior chip control.

- Corner R0.05 inserts are available, making it suitable for the machining of small work corner radii.

CUTTING PERFORMANCE

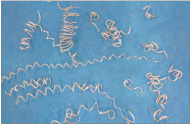

Chips when using a chip breaker

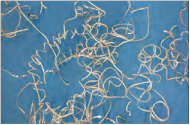

Chips made when no chip breaker used

<Cutting Conditions>

- Workpiece:

- Aluminium alloy

- Cutting Speed:

- 340m/min

- Feed:

- 0.1mm/rev

- Depth of Cut:

- 0.1mm

- Dry Cutting

<Cutting Conditions>

- Workpiece:

- Aluminium alloy

- Cutting Speed:

- 400m/min

- Wet Cutting: