BACK BACK |

- Technical Information

- Grade Profile

- Milling

- Coated Carbide(CVD&PVD)

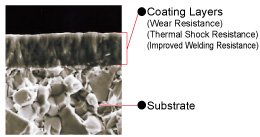

COATED CARBIDE(CVD&PVD)

CVD

- Special tough fibrous structure improves wear and fracture resistance.

- It covers a wide application range and thus reduces the number of tools required.

PVD

- PVD coating prolongs tool life.

- Coating of tools with sharp edges is possible without softening or changing the quality of the substrate.

SELECTION STANDARD

MILLING

GRADE CHARACTERISTICS

| Grade | Substrate | Coating Layer | ||

|---|---|---|---|---|

| Hardness (HRA) |

T.R.S (GPa) |

Composition | Thickness | |

| MC5020 | 91.0 | 2.2 | TiCN-Al2O3-Ti Compound | Thick |

| F5010 | 91.8 | 2.2 | TiCN-Al2O3-TiN | Thin |

| F5020 | 91.2 | 2.4 | TiCN-AI2O3-Ti Compound | Thick |

| F7010 | 89.0 | 2.6 | TiCN-Al2O3-TiN | Thin |

| FH7020 | 88.8 | 2.8 | TiCN-AI2O3-Ti Compound | Thick |

| F7030 | 88.8 | 2.8 | TiCN-Al2O3-TiN | Thin |

| VP15TF | 91.5 | 2.5 | (Al,Ti)N | Thin |

| VP20RT | 90.5 | 2.5 | (Al,Ti)N | Thin |

| VP30RT | 88.8 | 2.8 | (Al,Ti)N | Thin |

| UP20M | 90.5 | 2.0 | TiN | Thin |

*1GPa=102kg/mm2

FEATURES OF VP (MIRACLE) COATING

Compared to conventional coating technology, VP (MIRACLE) coating features (Al,Ti)N coating with highly increased heat resistance and adhesion strength.

APPLICATION EXAMPLES

| Tool | ASX445R0607E | |

|---|---|---|

| Insert (Grade) | SEMT13T3AGSN-JM (VP15TF) | |

| Workpiece |  |

|

| Component | Machine parts | |

| Cutting Speed (SFM) | 655 | |

| Feed per Tooth (IPR) | .011 | |

| Depth of Cut (inch) | .118 | |

| Results |  |

|

| Tool | AHX640WR0620F | |

|---|---|---|

| Insert (Grade) | NNMU200608ZEN-MK (MC5020) | |

| Workpiece |  |

|

| Cutting Speed (SFM) | 500 | |

| Feed per Tooth (IPR) | .013 | |

| Depth of Cut (inch) | .12 ─ .20 | |

| Results | MC5020 enables to extend tool life three times more than competitor’s CVD grade. | |

| Tool | BXD4000R2504 | |

|---|---|---|

| Insert (Grade) | XDGT1550PDFR-G04(LC15TF) | |

| Workpiece |  |

|

| Revolution(min-1 ) | 5,600 | |

| Cutting Speed(SFM) | 3,635 | |

| Depth of Cut(inch) | .157 | |

| Width of Cut(inch) | .059 | |

| Feed per Tooth(IPR) | .013 | |

| Chip Discharge(in3/min) | 57 | |

| Results | LC15TF produced a superior surface finish compared to the competitors non-coated carbide grade that generated a dull surface finish. | |

| Tool | AQXUR134SA12L | |

|---|---|---|

| Insert (Grade) | QOMT0934R-M2(VP30RT) | |

| Workpiece |  |

|

| Cutting Speed (SFM) | 260 | |

| Feed (inch/rev) | .004 | |

| Results | Tool life doubled. | |