BACK BACK |

- Technical Information

- Grade Profile

- Turning

- Sintered Diamond Pcd Grade MD220

SINTERED DIAMOND PCD GRADE MD220

- Suitable for materials such as aluminum alloy, non-ferrous metals, and fiber strengthened plastic.

- Suitable for extremely high speed finishing.

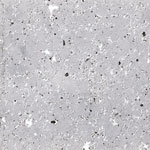

Micro-Structure of MD220

RECOMMENDED CUTTING CONDITIONS

TURNING

| Work Material | Recommended Cutting Condition | ||

|---|---|---|---|

| Recommended Cutting Speed (SFM) | Feed (inch/rev) | Depth of Cut (inch) | |

| Aluminum |

3280 (650─4920) | -.008 | -.200 |

| Aluminum Alloy (Si ≤ 16%) | 2630 (650─3940) | -.008 | -.200 |

| Aluminum Alloy (Si ≥ 16%) | 1970 (650─3280) | -.008 | -.118 |

| Copper Alloy | 2300 (650─3940) | -.008 | -.118 |

| Reinforced Plastic |

1970 (330─3280) | -.016 | -.079 |

| Glass Fiber Reinforced Plastic |

1640 (330─2630) | -.010 | -.079 |

| Carbon |

1210 (330─1970) | -.012 | -.079 |

| Ceramics |

165 (100─260) | -.004 | -.079 |

| Hard Rubber |

1970 (980─2630) | -.006 | -.039 |

| Wood Inorganic Board |

4260 (980─12100) | -.016 | ― |

| Tungsten Carbide |

50 (16─65) | -.008 | -.020 |

(Note) Not suitable for steel.

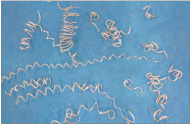

CUTTING PERFORMANCE

<Cutting Conditions>

- Workpiece

- : High Si Aluminum Alloy

- Insert

- : SPG422

- vc=655SFM

- ap=.059inch

- f=.006IPR

- Coolant

- : W.S.O

NEW PETIT CUT PCD INSERTS

FEATURES

-

Economical inserts

The small PCD delivers long tool life. Eliminates the need for regrinding, making tool management easier and economical. - PCD with chip breaker

Chip breaker formed directly on the PCD portion delivers superior chip control.  Corner R.002inch inserts are available, making it suitable for the machining of small work corner radii.

Corner R.002inch inserts are available, making it suitable for the machining of small work corner radii.

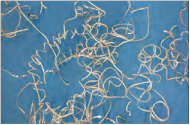

CUTTING PERFORMANCE

With chip breaker

<Cutting Conditions>

<Cutting Conditions>

- Workpiece

- : A5052

- Cutting Speed

- : 1115SFM

- Feed

- : .004IPR

Without chip breaker

- Depth of Cut

- : .004IPR

- Dry Cutting

<Cutting Conditions>

<Cutting Conditions>

- Workpiece

- : Aluminum Alloy

- Cutting Speed

- : 1310SFM

- Wet Cutting